Introduction to Digital Twin

A Digital Twin is a virtual replica of a physical object, system, or process. This concept is based on creating a digital model that accurately reflects its physical counterpart, allowing for real-time monitoring, simulation, and analysis. Digital Twins are used in various fields such as energy, manufacturing, healthcare, aerospace, and urban infrastructure.

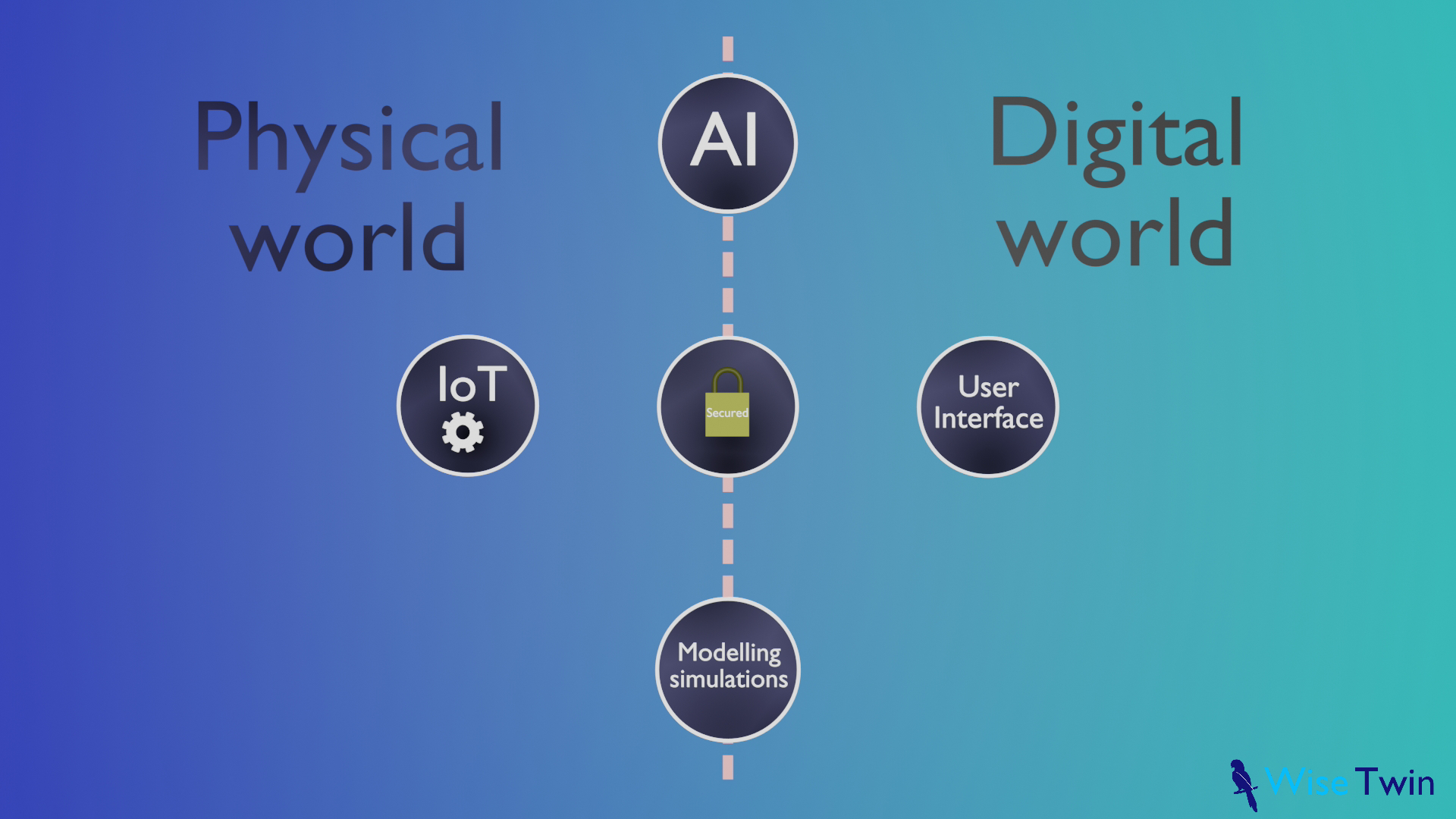

How Does a Digital Twin Work?

A Digital Twin is created by integrating data from sensors installed on the physical system. These sensors continuously collect information on performance, environmental conditions, and operational characteristics. The data is then transmitted to the digital replica, which uses advanced algorithms and machine learning technologies to analyze and predict future behaviors of the physical system.

- Data Collection: Sensors on the physical entity collect real-time data on various parameters such as temperature, pressure, motion, and more. These sensors are part of the Internet of Things (IoT) ecosystem, enabling continuous and detailed data streams.

- Integration: This data is integrated into the digital twin model through data lakes and advanced integration platforms, ensuring the virtual model remains up-to-date with the physical counterpart.

- Simulation and Analysis: Utilizing cutting-edge algorithms, machine learning, and artificial intelligence, the digital twin simulates different scenarios, predicts future states, identifies potential issues, and suggests optimizations. This includes the use of predictive analytics and digital simulations.

- Feedback Loop: Insights and recommendations from the digital twin are fed back to the physical entity, enabling real-time adjustments and improvements. This creates a continuous feedback loop that enhances efficiency and effectiveness.

Benefits of Digital Twins

Improved Efficiency: By simulating different scenarios and outcomes, businesses can optimize operations, reduce waste, and ensure peak performance.

Predictive Maintenance: Digital twins can predict equipment failures before they occur, allowing for proactive maintenance schedules that reduce downtime and maintenance costs.

Enhanced Product Development: Test and validate new designs in a virtual environment, accelerating the development process and reducing the need for physical prototypes.

Better Decision Making: Real-time insights and advanced analytics help stakeholders make informed decisions, improving overall strategy and operations.

Cost Savings: By reducing the need for physical prototypes and preventing downtime through predictive maintenance, digital twins contribute to significant cost savings.

Applications of Digital Twins

Energy

Digital twins are transforming energy production by enhancing efficiency, reliability, and sustainability. For instance, in wind energy, digital twins can optimize turbine performance by predicting maintenance needs, which can reduce operational costs by up to 35% and increase energy production by 15-25%. Similarly, in the oil and gas industry, digital twins help monitor and manage assets in real-time, potentially decreasing maintenance costs by 30% and extending asset life by 20%.

By simulating various scenarios and stress tests, digital twins enable energy producers to improve safety and avoid costly downtime. For power plants, digital twins can boost efficiency by up to 10% through real-time monitoring and predictive analytics, which helps in balancing supply and demand more effectively.

As the energy sector continues to integrate more renewable sources, the use of digital twins is crucial in managing the complexity of these systems, ensuring optimal performance, and supporting the transition to a more sustainable energy landscape. Learn more about Digital Twins in Energy

Warehouse Monitoring

Digital twins are pivotal in revolutionizing warehouse monitoring by providing a comprehensive digital replica of physical warehouse operations, enabling real-time tracking, predictive maintenance, and optimal resource management. These advanced models facilitate the seamless integration of IoT sensors and data analytics, resulting in enhanced operational efficiency and reduced costs.

For example, by leveraging digital twins, warehouses can achieve up to a 25% reduction in labor costs through optimized task scheduling and automation. Additionally, inventory management becomes significantly more accurate, reducing stockouts by 30% and overstock situations by 20%. Predictive maintenance enabled by digital twins can decrease equipment downtime by up to 30%, ensuring continuous operation and improving overall productivity. Moreover, energy consumption within warehouses can be optimized, leading to energy savings of up to 15%.

By providing detailed insights into every aspect of warehouse operations, digital twins help in identifying bottlenecks, streamlining workflows, and enhancing decision-making, thereby transforming the efficiency and effectiveness of warehouse management. Explore Digital Twins for Warehouse Monitoring

Smart Cities

Digital twins are essential for the development and management of smart cities, offering a sophisticated digital replica of urban environments that facilitates efficient planning, monitoring, and optimization of city operations. By integrating real-time data from various sources such as IoT devices, sensors, and public databases, digital twins enable city planners to simulate and analyze urban scenarios with unprecedented precision. This leads to significant improvements in resource allocation and infrastructure management.

For instance, cities can achieve up to a 30% reduction in energy consumption through optimized traffic management and smart grid implementations. Public transportation systems benefit as well, with potential reductions in operational costs by up to 20% and improvements in punctuality and efficiency by 15%. Moreover, digital twins enhance emergency response capabilities, potentially decreasing response times by 25% through real-time monitoring and predictive analytics. Additionally, urban planning is revolutionized by digital twins, which can reduce construction costs by 10-15% through better design and project management.

By providing a comprehensive, interactive model of the city, digital twins help create safer, more sustainable, and more resilient urban environments. Discover Digital Twins in Smart Cities

Smart Buildings

Digital twins are crucial for smart buildings, transforming how these structures are designed, operated, and maintained by providing a detailed, real-time digital replica of the building's physical and functional attributes. By integrating data from sensors and IoT devices, digital twins offer comprehensive monitoring and management capabilities that lead to significant operational efficiencies and cost savings.

For instance, energy consumption in smart buildings can be reduced by up to 20% through optimized heating, ventilation, and air conditioning (HVAC) systems, while predictive maintenance enabled by digital twins can lower maintenance costs by 25% and extend the lifespan of critical equipment by 20%. Occupant comfort and productivity are enhanced as well, with real-time adjustments to lighting and climate systems based on usage patterns and preferences. Furthermore, digital twins facilitate improved space utilization, potentially increasing occupancy rates by 15% through data-driven insights and adjustments. Security is also bolstered, with integrated systems providing real-time monitoring and faster response times to incidents.

Overall, digital twins play a pivotal role in creating more efficient, sustainable, and comfortable smart buildings. Understand Digital Twins in Smart Buildings

4.0 Industry

Digital twins are integral to 4.0 Industry, driving the transformation of manufacturing and industrial operations through advanced digital replication of physical assets and processes. These sophisticated models enable real-time monitoring, simulation, and optimization, leading to substantial improvements in efficiency and productivity.

For instance, digital twins can reduce manufacturing downtime by up to 30% through predictive maintenance, anticipating equipment failures before they occur and scheduling timely interventions. They also enhance production quality, with potential reductions in defect rates by up to 25% by continuously analyzing and optimizing production processes. Inventory management sees significant benefits, with stock levels optimized and carrying costs decreased by 20% due to precise demand forecasting and real-time tracking. Additionally, energy consumption in industrial facilities can be lowered by 15%, as digital twins allow for more efficient operation of machinery and systems.

By facilitating seamless integration of cyber-physical systems, IoT, and big data analytics, digital twins empower manufacturers to achieve higher levels of agility, flexibility, and responsiveness, making them a cornerstone of the 4.0 Industry revolution. Dive into Digital Twins for 4.0 Industry

Future of Digital Twins

The future of Digital Twins is incredibly promising, with advancements in AI, machine learning, and IoT driving further innovation. As technology evolves, the accuracy and capabilities of Digital Twins will continue to expand, opening new possibilities for various industries. The integration of edge computing, 5G, and blockchain technologies will further enhance the capabilities and security of Digital Twins.

Learn More

Ready to dive deeper? Check out our FAQ covering different aspects of our large offer on Digital Twin technology:

Stay tuned for more updates and insights on Digital Twins. Do not hesitate to reach out to us using the contact form